Summer Cooling Tower Maintenance: The Crucial Role of Disinfection

As the UK enters the warmer summer months, cooling towers face a perfect storm of microbial risk. Higher temperatures, increased system demand, and greater sunlight exposure all contribute to rapid microbial proliferation, including bacteria, algae, and Legionella - posing operational, health, and compliance risks.

In this season, chlorine-based disinfection becomes more than a routine treatment - it’s a critical safeguard.

Why Summer Increases Microbial Risk

During summer, several seasonal factors can destabilise water systems:

Higher water temperatures encourage microbial growth

Extended run times due to heavier cooling loads

Increased UV exposure promotes algae bloom

Evaporation and concentration cycles can shift water chemistry and reduce biocide effectiveness

If left unchecked, this can lead to:

Heat transfer inefficiency due to biofouling

Corrosion from microbial by-products

Legionella proliferation and regulatory non-compliance

A strong biocidal strategy - backed by regular monitoring - is essential.

Chlorine: A Proven Summer Solution for Cooling Towers

Chlorine remains a cornerstone in summer cooling water treatment, thanks to its:

Fast-acting and broad-spectrum efficacy

Residual protection throughout the system

Compatibility with online dosing and control systems

Cost-effective and scalable performance

Common forms of chlorine in industrial water treatment include:

Sodium Hypochlorite (NaOCl) - a fast-release oxidising biocide

Stabilised Chlorine Donors - for controlled release

Chlorine-releasing compounds - useful for shock dosing

The Importance of pH on Biocide Performance

Biocide effectiveness is not just about dosage - pH plays a critical role, especially in summer when system chemistry can fluctuate.

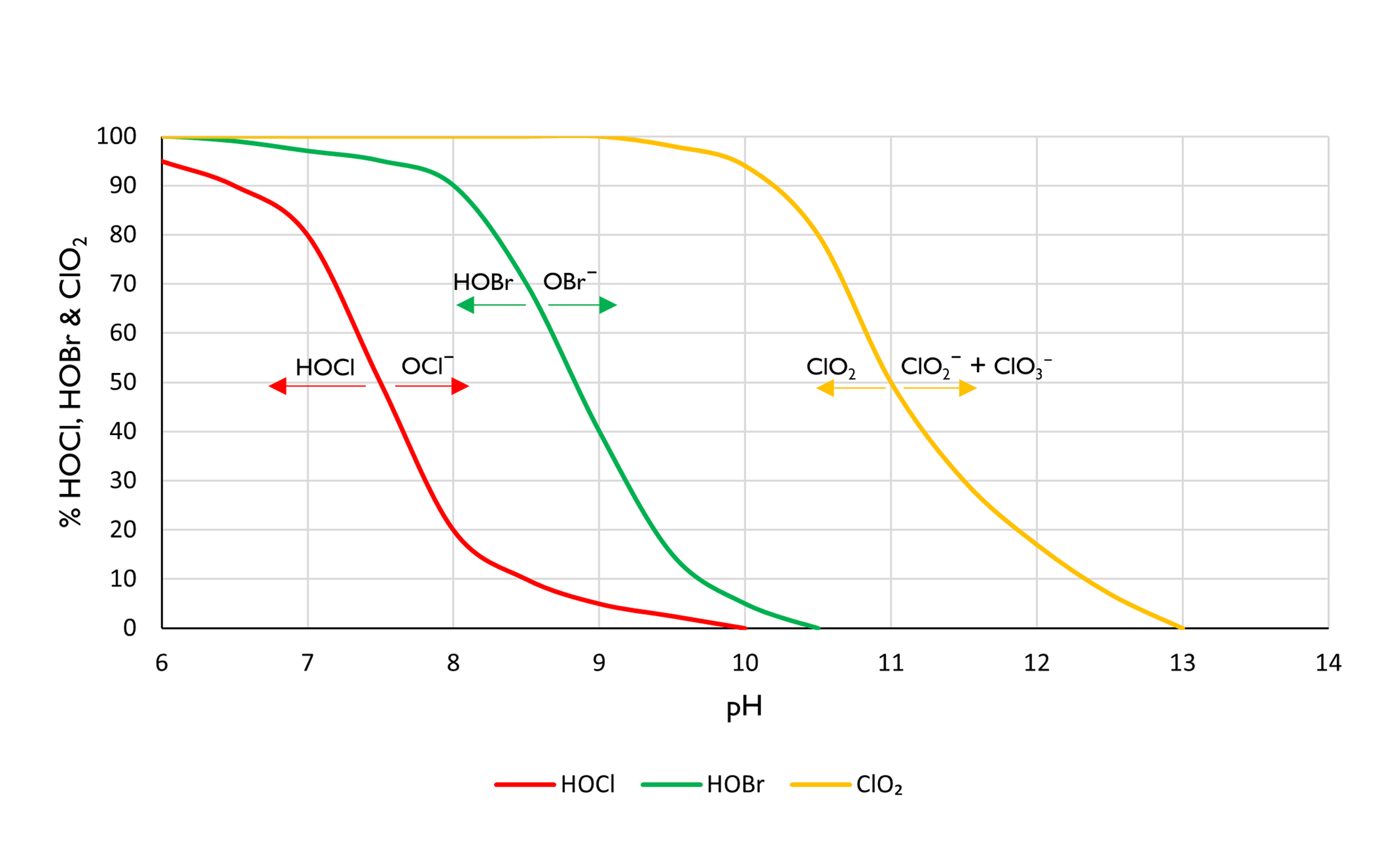

The graph below illustrates the relationship between pH and the percentage of active biocide present in three commonly used oxidising biocides: hypochlorous acid, hypobromous acid, and chlorine dioxide. (All available as options on the WTP product range)

Adapted from ‘The Nalco Water Handbook’, 4th ed., McGraw Hill, and ‘Using Chlorine Dioxide for Effective Water Treatment’, A. Gupta and S. Muench, Process Cooling (2016).

Key takeaways:

Hypochlorous acid (the most effective form of chlorine) dominates at pH 6.5-7.5

At pH above 8, chlorine shifts to hypochlorite, which is significantly less active

Chlorine dioxide maintains consistent biocidal strength across a broader pH range

This highlights the importance of monitoring and adjusting pH to ensure biocides perform as intended.

Routine Testing: Essential for Summer Control

Maintaining a safe and efficient cooling system over the summer requires more than just chemical dosing - it requires constant oversight. At WTP, we provide a complete range of water testing tools to support your programme:

Chlorine Test Kits – for measuring free and total chlorine

Photometers – for digital, multi-parameter analysis

Test Strips – for quick, on-the-spot chlorine and pH checks

Dipslides – for monitoring microbial load and biofilm presence

These tools help ensure that your disinfection programme remains within control limits and aligned with regulatory guidance such as ACoP L8 and HSG274 Part 1.

WTP: Supporting You with Chlorine and More

Water Treatment Products supplies a wide range of oxidising biocides and the testing tools needed to manage them effectively. Our technical team can support you with product selection, dosing strategies, and on-site troubleshooting to ensure your cooling systems remain compliant, efficient, and safe throughout the summer season.

Whether you need fast-acting oxidising agents for high-demand conditions or stabilised products for long-term performance, WTP has a solution to suit your site’s specific requirements.

In Summary

With increased microbial risk in summer, effective cooling tower treatment is essential. Disinfection, when properly managed and supported by robust testing and pH control, provides a reliable, cost-effective way to maintain system performance and safety.

Now is the time to assess your summer water treatment programme - ensure your biocide is working as hard as your cooling system is.