Why Do We Use Chemical Inhibitors in Closed Heating Systems

Published: September 2025

At Water Treatment Products (WTP), our technical team recently carried out a baseline corrosion trial to demonstrate the impact of untreated water in closed heating systems. This experiment forms part of our ongoing development and testing programme, ensuring our products deliver proven performance.

Why We Ran This Trial

As a leading UK manufacturer of water treatment chemicals, we understand how important it is to back up our product claims with robust testing. This trial was designed to establish a control benchmark, showing what happens when no inhibitor is used. The results from untreated water were compared with water treated with our most widely used molybdate/nitrite inhibitor - WTP M27.

Testing

Two test rigs based on the NSF specification were set up, one for soft and one for hard water without any chemical treatment. Initially both rigs run with no inhibitor and then repeated with the M27 @1%. Corrosion rates were measured using corrosion coupons to ASTM standards. This test was performed to assess the impact of untreated water on common system components over a test standard period, compared to treated. The data taken from this experiment has been compared against the NSF CIAS guidelines for corrosion inhibition.

Corrosion Rate Results

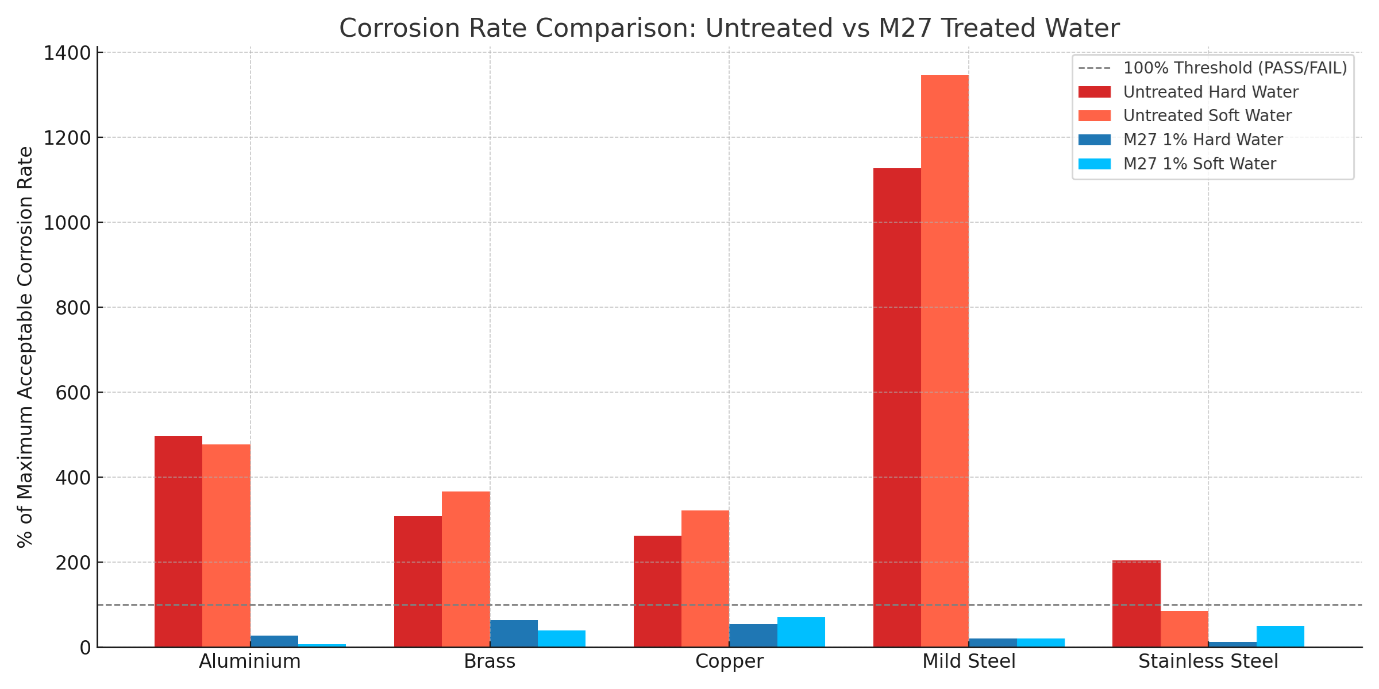

The results below show the corrosion rates for both treated and untreated waters as a percentage of the maximum allowable rates set out in the NSF CIAS standards.

We calculated corrosion rates as a percentage of the maximum allowable rates defined by NSF CIAS industry standards. In this framework, 100% represents the maximum allowable corrosion rate for a closed system water. Values below 100% are classified as a PASS, while those exceeding 100% are classified as FAIL. A percentage of 498% therefore equates to 4.98 times greater than the maximum allowable corrosion rate.

Graphical Comparison

Figure 1

Shows the coupons removed from the untreated water test.

Figure 2

Shows the visual condition of the coupons removed from the treated water.

Why This Matters

Corrosion isn’t just an aesthetic issue - it compromises system performance, increases energy use, and can result in complete component failure. This small-scale simulation reinforces what engineers and installers already know: water quality must be actively managed.

The results of this trial support industry guidance from BS 8552 & BG50, both of which stress the importance of dosing, testing, and maintaining closed systems with suitable inhibitors.

Our Conclusion

These results show that untreated water exceeded the acceptable corrosion threshold by many multiples, particularly for mild steel and aluminium. In contrast, WTP M27 at just 1% concentration demonstrates that there are substantial benefits gained by using chemical treatments.

The results send a clear message: leaving systems untreated can cause rapid corrosion, even in a short timeframe.

Our technical team is always available to advise on product selection, dosing strategies, and compliance with UK standards.